What Size Bump Stops Do I Need

Hydraulic Bump Cease Guide

Hydraulic bump stops, or air-bumps as they are sometimes chosen, are a critical component of any performance suspension organisation. Not simply do they help protect the vehicle and suspension components from hard bottom-outs, they play a critical office in end-stroke damping.

As you can meet from the above cut-away, hydraulic crash-land stops are far more than a simple air-cylinder, they have a total piston with compression and rebound shims only like a operation shock cushion.

How Does a Hydraulic Crash-land Cease Work?

Hydraulic bump stops are filled with shock oil and nitrogen pressure. During the starting time phase of the bump finish stroke, the shaft and piston compress the nitrogen pressure level which acts like a spring with an exponentially increasing spring rate. This allows the first 1/iii of the stroke to be relatively soft with the middle 1/iii beingness significantly stiffer. The last i/three of the stroke (depending on oil level) is the second stage where the shock piston is forced through the shock oil and that is where the majority of the free energy is captivated. Of course, once compressed, that energy wants to be released so rebound valving is used to help prevent hard unloading of the bump end.

While some customers are deterred by the cost of hydraulic bump stops, particularly when compared to cheap safety bumps, yous definitely do get what you pay for. King Hydraulic Bump Stops are priced a bit higher than most other brands simply making a bump finish that withstands high forces repeatedly for the duration of a long desert race requires high quality materials machined to very tight tolerances.

This hydraulic bump finish guide is ©Copyright Crawlpedia.com - Do not reproduce or repost without written approval.

Crash-land Stop Brands and Styles

Simply most every performance off-route shock manufacturer makes their own hydraulic crash-land stop and, simply similar with their shocks, they all do things slightly different to attempt and gear up themselves apart.

King and ADS both build their bump stops similar they build their shocks with full size pistons, pinch and rebound shims, and high pressure seals. While nosotros used their larger 2.five size bumps stops for our displays, when compared in matching sizes to other brands, their components are withal significantly beefier. Both Rex and ADS crash-land stops are elevation mounted and fit using precision machined mounting sleeves instead of traditional pinch-mode cans.

Fox hydraulic bumps stops are extremely pop due to their affordability and while their components are smaller and designed for mass manufacturing similar their shocks, we've had very good luck with them over the years and would highly recommend them to customers on a upkeep.

Bilstein crash-land stops are practically identical to those made by Fox other than a rebound spring put in place of the shaft spacer. The jump is designed to help dampen the unloading forces of the bump terminate and preclude that annoying clicking sound cause past the bump finish fully extending.

SPC Performance (Calorie-free Racing) calls their hydraulic bump stop a Jounce Shock due to its unique design. Unlike a traditional piston style bump stop, the Jounce Daze dampens both compression and rebound motion by forcing oil though externally adjustable needle valves instead of valving shims. This design makes the Jounce shock extremely meaty, allowing it to fit in spaces that a traditional crash-land terminate could not. I downfall to the Jounce Shock is that the style that it is made makes it extremely hard to open up and service without damaging it.

What Size Bump Stop Practise I Need?

Hydraulic bump stops are typically bachelor in two.0" and two.5" body sizes with ii", 3", and four" stroke lengths which can also be shortened with the use of internal spacers. Just similar when measuring for performance shocks, the cylinder diameter is decided by the weight of the vehicle and how information technology is used and the stroke length is determined by your interruption travel and where your bump stops will be mounted.

2.0 Bump Stops work best for solid axle vehicles v,000 lbs. or nether used for stone crawling, trail running, and mild desert runs. For vehicles with low (4-5" upwardly travel) ride heights, we recommend 3" stroke bump stops if you lot can fit them or ii" stroke bumps if you are tight for infinite. For vehicles with ride heights higher up half-dozen-vii", we suggest full 4" bump stops.

2.5 Crash-land Stops can absorb significantly more than energy than the 2.0 size so they are better suited for solid axle vehicles over v,000 lbs. or in highly leveraged a-arm/trailing arm applications. Mud trucks and desert racers with large amounts of suspension travel should run four" travel bump stops, while vehicles with a-artillery or low ride heights should use 2" or three" travel crash-land stops.

Shorter bump stops require college internal pressures than longer bump stops which results in a harder touch. Therefore, you e'er want to fit the longest crash-land stops you lot can that don't interfere with your up travel or crusade you to be riding on them at ride acme.

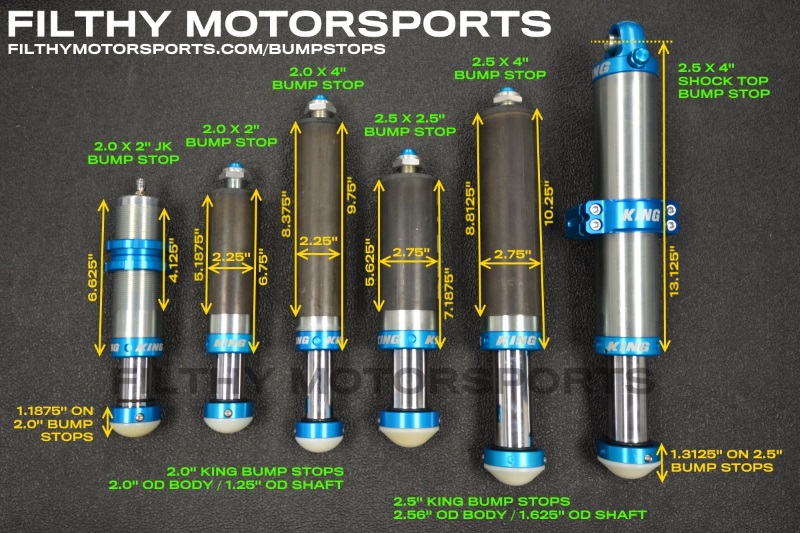

New! Rex hydraulic bump terminate dimension courtesy of Filthy Motorsports:

Tuning Hydraulic Bump Stops

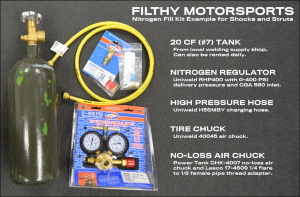

Bump stops are tuned by adjusting their internal nitrogen pressure using a nitrogen fill kit which includes a pressure regulator, connection hose, and an air chuck. Getting them fix correctly is a trial and fault process and we notice it works best to start with a pressure that is too high (350-400 psi) and slowly work your fashion downwards. With the bump stop pressurized, gyre the o-ring on the shaft all the fashion up before going out for your start test run. You will detect that as your bump stops cycle, they will button the o-rings down to show you how much they have moved. Ultimately, when y'all are driving 95% all out, you want the bump stops to cycle almost all the manner leaving nigh 1/iv" left as insurance for those times when you hit something harder than you had expected.

Gather a nitrogen fill kit with these parts from Amazon.

The only other item needed is a nitrogen tank, available at any welding supply shop.

Links volition non appear if you have ad blocker turned on.

*Crawlpedia earns a small commission on Amazon purchases which does not affect pricing.

This hydraulic crash-land stop guide is ©Copyright Crawlpedia.com - Do not reproduce or repost without written blessing.

Related Resources

Crawlpedia Shock Shootout

4-Link Suspension Guide

Shock Tuning Guide

Shock Valving Guide

Daze Valving Shim Stack Examples

How To Measure out For Coilovers

Coilover Install and Setup Guide

Coilover Spring Re-Calculation Guide

Coilover Leap Rate Calculator

ORI STX Struts Guide

Filthy Motorsports

Crawlpedia is proudly supported by Filthy Motorsports, a specialty off-road racing and 4x4 parts shop in Boulder, Colorado.

Annunciate Here!

Want to see your banners and links on Crawlpedia? It's like shooting fish in a barrel, affordable and very effective, just contact united states of america to get started!

Street Legal Laws

To find the street legal laws for your state including maximum intermission lift heights and tire size rules visit LiftLaws.com

What Size Bump Stops Do I Need,

Source: https://www.crawlpedia.com/bump_stops.htm

Posted by: davisthaverom67.blogspot.com

0 Response to "What Size Bump Stops Do I Need"

Post a Comment